LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

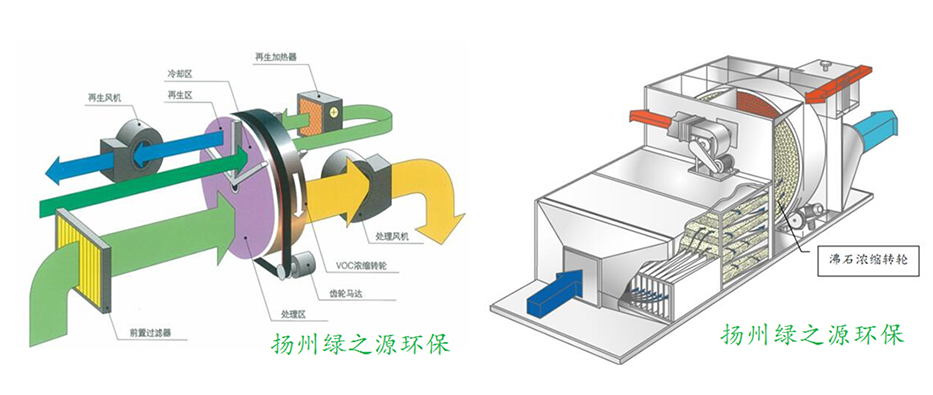

The zeolite rotor adsorption and concentration device adopts three continuous procedures of adsorption-concentration-desorption incineration, which is mainly used for the treatment of organic waste gas; it is especially suitable for large air volume and low concentration occasions. The adsorption device uses ceramic fiber as the base material, and is made into a honeycomb-shaped large disc wheel-shaped system, and the surface is coated with hydrophobic zeolite as an adsorbent. The zeolite runner adsorption and concentration device is mainly composed of waste gas pretreatment system, zeolite runner concentration and adsorption system, desorption system, cooling and drying system and automatic control system.

6. Exhaust treatment in the process of lithium ion battery manufacturing (electrode formation process, electrolyte filling process).

The concentration runner is cooled in the cooling zone, and the air passing through the cooling zone is heated and used as regeneration air to achieve the effect of energy saving.

Five,:various VOC corresponding performance list

| Type | Name | Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ |

Aliphatic | n-Ethane | ○ | ◎ | ◎ | ○ | ◎ |

Cycloethane | ○ | △ | △ | ○ | △ | |

Alcohol | Methanol | △ | △ | △ | △ | ○ |

Ethanol | △ | ○ | △ | △ | ◎ | |

n-Propanol | ○ | ○ | ○ | ○ | ◎ | |

Isopropyl alcohol(IPA) | ○ | ○ | ○ | ○ | ◎ | |

n-Butanol | ○ | ○ | ○ | ○ | ◎ | |

Diacetone alcohol | ○ | ○ | ○ | ○ | ○ | |

Ketone | Acetone | △ | △ | ○ | △ | ◎ |

Methyl ethyl ketone (MEK) | ○ | ◎ | ◎ | ○ | ◎ | |

Methyl Butanyl Ketone (MIBK) | ◎ | ◎ | ◎ | ◎ | ◎ | |

Methyl Amyl Ketone (MAK) | ◎ | ◎ | ◎ | ◎ | ◎ | |

Methyl propyl ketone | ◎ | ◎ | ◎ | ◎ | ◎ | |

Cyclohexanone | ◎ | ◎ | △ | ◎ | △ | |

Ester | Ethyl acetate | ○ | ◎ | ◎ | ◎ | ◎ |

n-Butyl acetate | ◎ | ◎ | ◎ | ◎ | ◎ | |

Methyl ethoxyethyl ester | ◎ | ◎ | ○ | ◎ | ○ | |

Ethylene glycol butyl ether acetate | ◎ | ◎ | ○ | ◎ | ○ | |

Butyl ethoxyethyl ester | ◎ | ◎ | ○ | ◎ | ○ | |

1-Dimethyl-2-propyl acetate (PGMEA) | ◎ | ◎ | ○ | ◎ | ○ | |

Ether | Methyl cellosolve | ◎ | ◎ | ◎ | ◎ | ◎ |

Cellosolve | ◎ | ◎ | ○ | ◎ | ○ | |

Butyl Cellosolve | ◎ | ◎ | ○ | ◎ | ○ | |

1-Dimethyl-2-propanol | ◎ | ◎ | ◎ | ◎ | ◎ | |

Aromatic | Benzene | △ | ○ | ○ | △ | ○ |

Toluene | ○ | ◎ | ○ | ◎ | ○ | |

o-Xylene | ◎ | ◎ | × | ◎ | × | |

m-Xylene | ◎ | ◎ | × | ◎ | × | |

p-Xylene | ◎ | ◎ | ○ | ◎ | ○ | |

Vinyl | × | × | ◎ | × | × | |

Ethylbenzene | ◎ | ◎ | ○ | ◎ | ○ | |

Chlorine | Dichloromethane | △ | △ | ○ | △ | ○ |

Trichloroethyl | △ | △ | ○ | △ | ○ | |

Other | N-methyl-2-alkanone | ◎ | ◎ | △ | ◎ | △ |

Dimethylformamide (DMF) | ○ | ◎ | ◎ | ○ | ◎ | |

Dimethylacetamide (DMAC) | ◎ | ◎ | ○ | ◎ | ○ | |

Dimethylcarbonamide (DMC) | ○ | ◎ | ◎ | ○ | ◎ | |

Tetrachlorofuran (THF) | ○ | ○ | ◎ | ○ | ◎ | |

Note: ◎--Excellent ○--Good △--Medium ×--Low | ||||||

SIX:Runner parameters

Model | Handling air volume m3/h | Wheel diameter mm | Dimensions mm |

LZX-120 | 5400~9000 | 1220 | 1500×1940×1600 |

LZX-150 | 9000~12000 | 1525 | 1750×1940×1850 |

LZX-170 | 12000~15000 | 1730 | 1950×1940×2050 |

LZX-190 | 15000~18000 | 1940 | 2150×1940×2250 |

LZX-210 | 18000~24000 | 2190 | 2400×2000×2500 |

LZX-240 | 24000~30000 | 2450 | 2700×2000×2825 |

LZX-260 | 27000~35000 | 2650 | 2900×2000×3125 |

LZX-290 | 33000~44000 | 2950 | 3200×2000×3325 |

LZX-320 | 42000~53000 | 3250 | 3600×2000×3750 |

LZX-350 | 53000~63000 | 3550 | 3900×2100×4050 |

LZX-370 | 63000~69000 | 3750 | 4200×2100×4350 |

LZX-390 | 69000~78000 | 3950 | 4400×2100×4550 |

LZX-420 | 78000~90000 | 4250 | 4700×2100×4800 |